Spatial computing & extended reality

Why Manufacturing Leaders Are Investing in Spatial Simulation

Yet, for many manufacturing leaders, a critical paradox threatens this momentum. You acquire cutting-edge equipment to boost production capacity and capability, often shipping it from plants halfway across the globe. But to unlock the value of this machinery, you face a dilemma: you cannot train your workforce because the equipment has not arrived, or worse, it is already here but too busy meeting production quotas to be spared for training sessions.

While production drives value, it consumes the time needed for training, inadvertently creating future deficits. The mandate for operational throughput stands at odds with the requirement for workforce readiness. However, a new solution has emerged, one that decouples learning from physical reality.

Moving Beyond Static Manuals

Industrial training has been stuck in a cycle of stagnation. We rely on static PDFs, dense manuals, and passive videos, expecting operators to translate complex mechanical concepts from flat, 2D documents into real-world skills. This approach fails to build genuine competency, creating a heavy dependency on On-the-Job Training (OJT).

Consequently, learners must compete for the time of senior operators who are often already overextended. This creates a critical bottleneck: if the trainer is unavailable or production schedules cannot accommodate machine downtime, learning halts. The result is inconsistent training quality and a dangerously long time-to-competency.

What is Spatial Simulation?

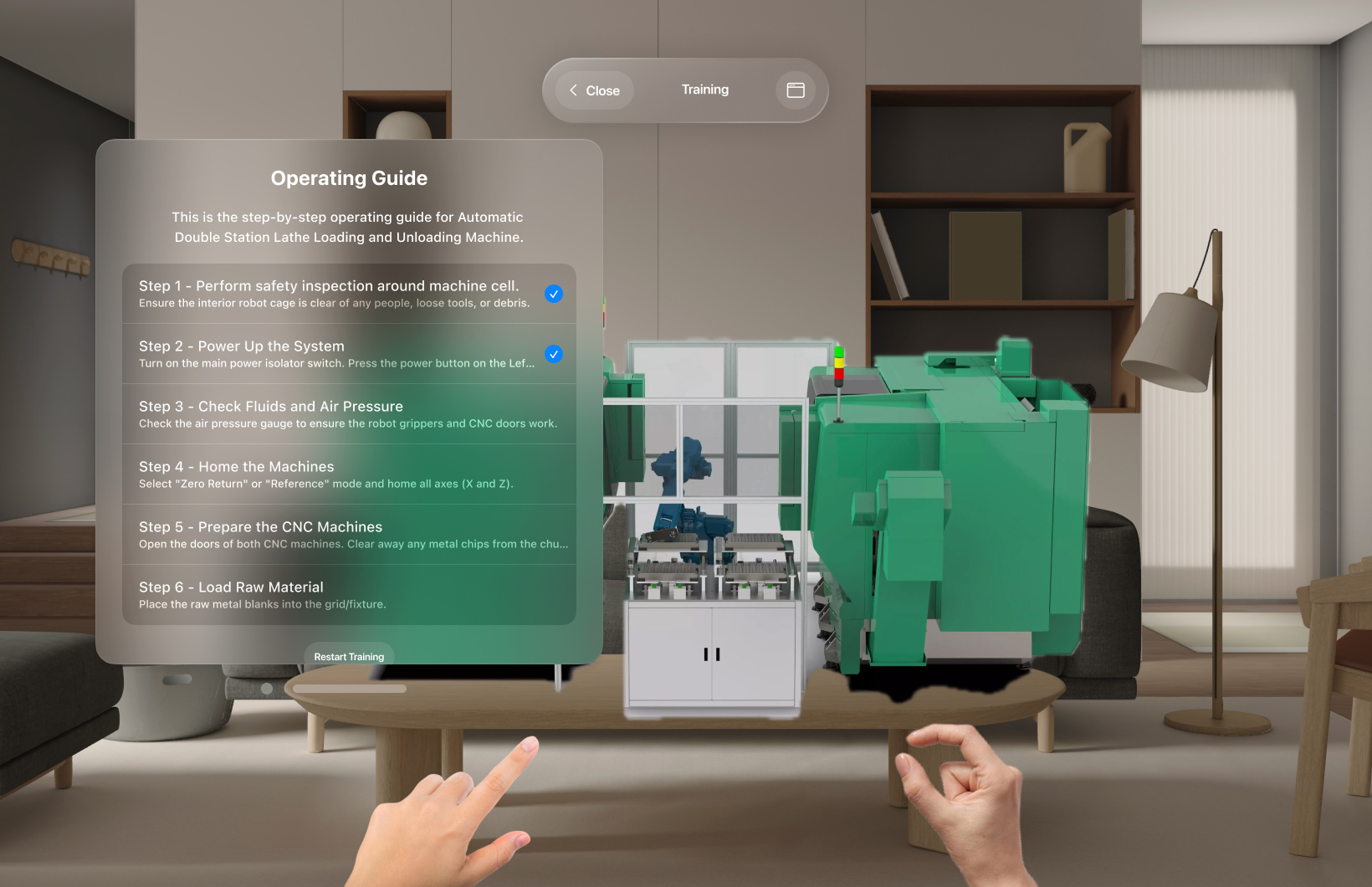

To solve this, forward-thinking organisations are turning to spatial simulation, a strategic application of spatial computing and immersive media for immersive training and simulation.

At its core is the digital twin—an exact, interactive 3D replica of your physical machinery. Unlike a flat video, a digital twin possesses depth and dimension. It allows an operator to stand before a virtual machine, walk around it, and interact with it using natural hand gestures. It transforms the training environment from a classroom into a virtual factory floor.

Harnessing Spatial Simulation for Operational Excellence

By leveraging spatial simulation, leaders can bridge the gap between intention and execution in four critical areas:

The most immediate value is the ability to train before the equipment physically exists in the plant. When moving machinery between global sites, there is often a lag of weeks or months. With spatial simulation, operators can begin their training immediately. They familiarise themselves with the machine’s footprint and interface, ensuring that on day one of delivery, the team is ready to operate.

In manufacturing, speed is essential. Many plants aim for an ideal, short changeover time (the time taken to switch a line from one product to another). Achieving the ideal time requires precise muscle memory. Spatial modules allow learners to rehearse the specific actions and gestures required for a changeover repeatedly. This builds confidence and speed in a risk-free environment, independent of the physical machine’s availability.

Physical training has limits; you cannot easily dismantle a working machine to show a trainee what happens inside. Spatial computing unlocks the "exploded view". An operator can virtually separate the machine’s components to visualise how internal parts function. This deepens technical understanding and contextualises how a single error can impact the entire system.

The Strategic Investment

The shift to spatial simulation is not merely about technology; it is about business outcomes and empowering the people who keep the plants running.

Scalability: You remove the dependency on a single trainer’s schedule. A digital module scales instantly across global teams, ensuring every operator receives the same high standard of instruction.

Standardisation: Assessment becomes objective. Rather than relying on a trainer’s subjective judgement, the system runs a timed assessment of the simulated changeover. A pass means the operator has proven they can perform the task within the set time target.

ROI: By reducing the "time to competency," you accelerate the time it takes for new equipment to become profitable.

The Future: A New Standard of Readiness

The leaders who leverage spatial computing today are not just buying the latest gadgets; they are investing in a workforce that is faster, safer, and more autonomous. We are moving away from a world where we wait for machinery to be available, and into an era where readiness is on-demand. The future of manufacturing is about the digital ecosystem that empowers the people who run it.

Key Takeaways

Spatial Simulation lets you train without stopping the factory

Spatial Simulation builds real skills faster than reading manuals by letting workers use their hands to practice tricky repairs and see inside the machine virtually

Spatial Simulation makes teams ready while reducing dependencies on equipment and trainer availability